Views: 0 Author: Site Editor Publish Time: 2023-01-07 Origin: Site

An aquatic feed extruder is a machine used to manufacture feed for aquatic animals. It typically consists of an extrusion portion, a feeding portion, a mold portion, and a control system portion.

An aquatic feed extruder includes an extrusion shaft and a corresponding mold, which is used to compress feed raw materials into the desired shape and size of the feed. The feeding portion is usually a hopper or conveyor belt that transports the feed raw materials to the working area of the extrusion shaft. The mold portion includes a set of interchangeable molds that are used to extrude the feed into the desired shape. The control system portion includes an electrical controller, electrical components, and a human-machine interface, which are used to control and monitor the entire machine.

There are many types of aquatic feed extruders, including single-screw extruders, twin-screw extruders, and multi-screw extruders. Among them, the twin-screw extruder is the most commonly used, and its working principle is to compress and extrude the feed raw materials through a rotating screw. The working principle of the twin screw extruder and the multi-screw extruder is similar to that of the single screw extruder, but they have a higher production capacity and a larger pressure.

Aquatic Feed Process lines have many advantages, including high production efficiency, low cost, easy operation, and flexible molding. They can be used to produce a variety of aquatic feeds, including floating feeds, sinking feeds, and slow-sinking feeds, for different aquatic animals, such as fish, shrimp, and crabs. In addition, the extruded feed has good stability in water, high digestibility, and good palatability, which can improve the growth and health of aquatic animals.

Aquatic feed extrusion machine can produce feed for various aquatic animals, including fish, shrimp, and other marine animals. It typically uses a variety of raw ingredients such as grains, proteins, and other nutrients, and processes them into a finished feed product through a process called extrusion. The feed is usually shaped into small pellets or flakes, which can be easily consumed by aquatic animals.

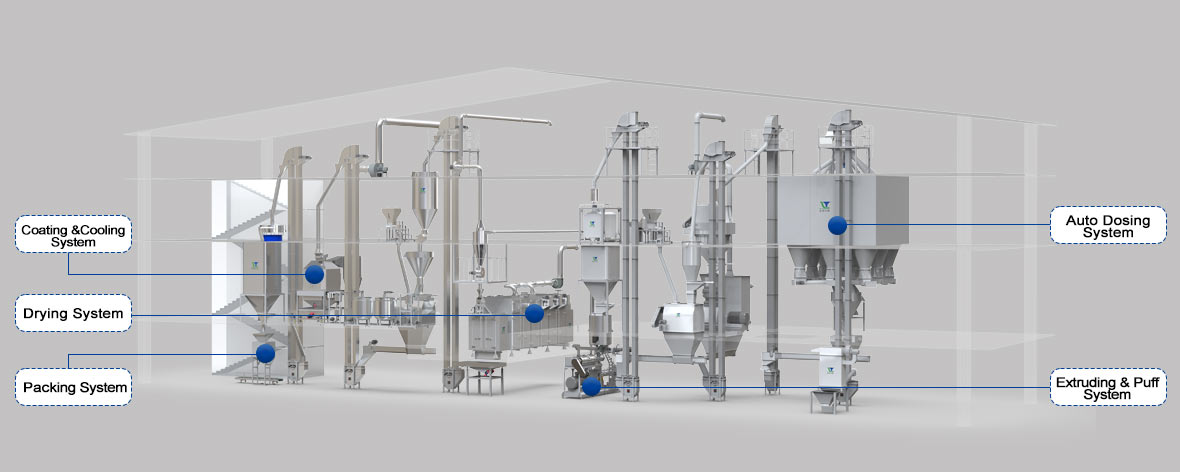

The production process of aquaculture feed using an extruder generally includes raw material grinding, raw material mixing, raw material extrusion, and drying. The first step is to grind the raw materials, such as cereals, beans, and fishmeal, into a fine powder. The second step is to mix the ground raw materials with water and other additives, such as vitamins and minerals, to form a dough-like mixture. The third step is to use the extruder to compress and extrude the mixture into the desired shape and size of the feed. The fourth step is to dry the extruded feed to a certain moisture content to ensure its stability and storage.

Aquatic feed extrusion technology has been widely used in the feed industry in recent years due to its many advantages. It can not only improve the utilization rate of feed raw materials but also improve the quality and stability of the feed. In addition, the extrusion process can kill harmful microorganisms and parasites in the feed, which can reduce the risk of disease transmission in aquatic animals. However, the extrusion process also has some limitations, such as the need for high-quality raw materials and the inability to process certain types of raw materials, such as whole fish and oilseeds.

In conclusion, aquatic feed extrusion machine are an important and effective tool for the production of aquatic feed. They have many advantages, such as high production efficiency, low cost, and good feed quality. However, they also have some limitations, and their use should be carefully considered in the context of specific feed production needs.

For more information about aquatic feed process line, please kindly send an inquiry, and the sales manager will send you technical solutions right away.

Email:arrow@znmachinery.com

Whatsapp:+8615863179132