| Availability: | |

|---|---|

| Quantity: | |

Hot Air Cross Circulation Dryer/Drying Machine

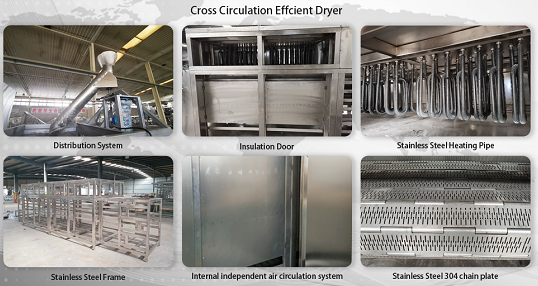

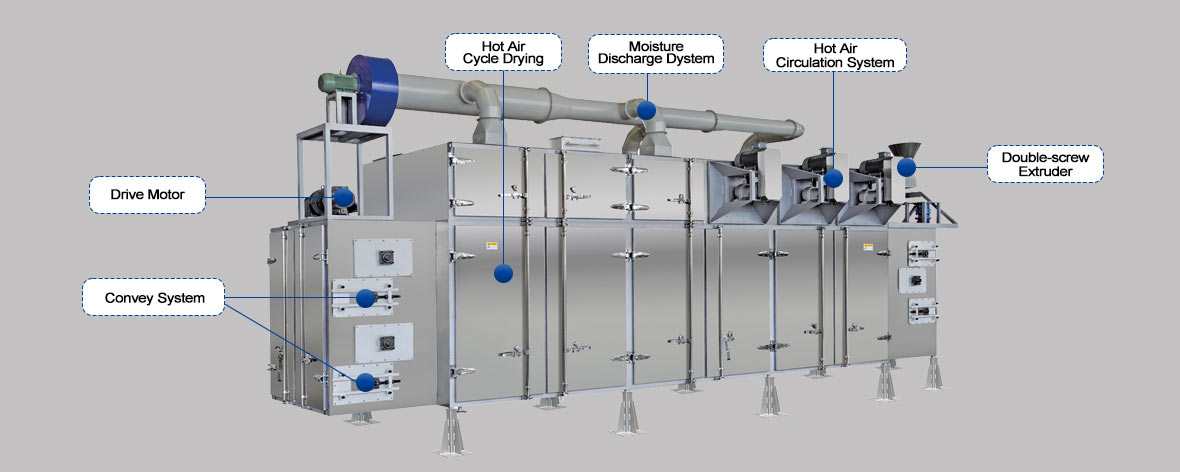

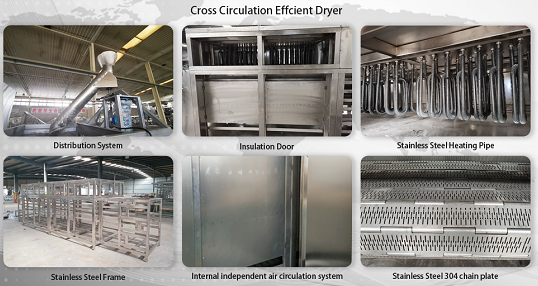

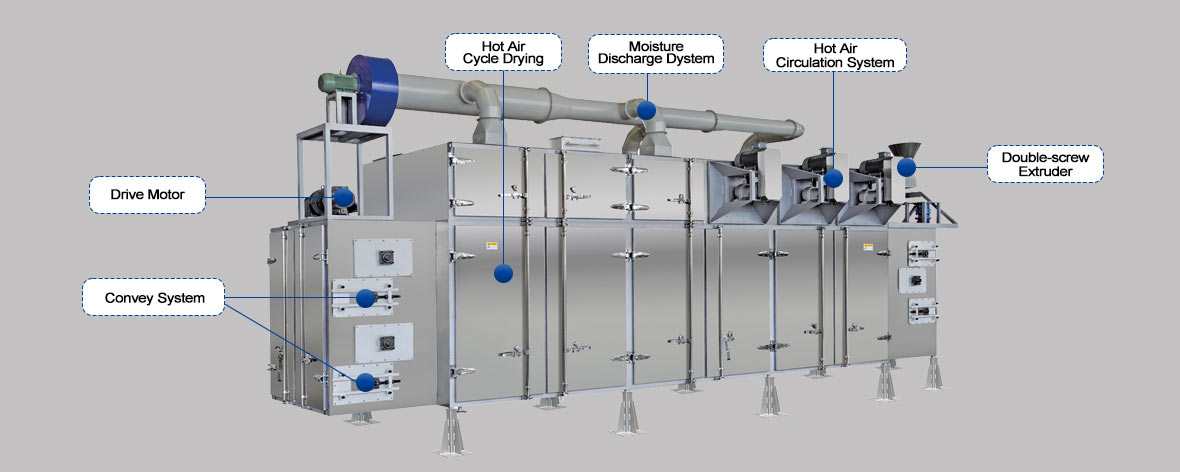

Cross Circulation Efficient Dryers are specialized equipment designed for the high-capacity and high-moisture drying of various food products, such as soya protein, pet food, aquatic feed, and more. Cross Circulation Efficient Dryers are typically used to remove moisture from the products and improve their water resistance and appearance quality. The dryers use a hot air circulation bi-directional cross-flow method, where hot air is circulated through the dryer in a cross-flow pattern to penetrate the materials from top to bottom. A moisture exhaust fan is also included in the dryer to remove moisture from the products as they are dried. The design of the Cross Circulation Efficient Dryers allows for efficient and effective drying of large quantities of material, making it suitable for commercial and industrial applications. Customization options are also available according to the customer's specific needs, such as capacity, moisture level, temperature control, or any other requirements.

What is this High Efficiency By-Cross Dryer Used for?

Cross Circulation Efficient Dryers are versatile machines that can be used to dry a wide range of products. As you mentioned, these dryers can be used to dry food products such as fruits, vegetables, meat, fish, seafood, grains, nuts, and many other types of food products. It can also be used in the feed industry to dry animal feed, pet food, and aquatic feed.

In addition, these dryers can also be used in other industries such as the pharmaceutical, chemical, and wood products industries, to dry powders, granules, tablets, and wood chips. It can also be used for drying materials such as grains, herbs, spices, and many other types of products. The efficiency and versatility of this type of dryer make it a valuable asset for many different types of manufacturing and production processes.

High-efficiency dryers are designed to effectively and efficiently remove moisture from a wide range of products.This also helps to maintain the shape, color, and texture of the product, ensuring a good quality finished product.the dryer may also include temperature and humidity sensors, which allow for real-time monitoring and control of the drying process. This can ensure that the drying process is done at the optimal conditions for the product, and prevent any damage to the product.

The large capacity dryers are also equipped with features that are designed to improve the water resistance and appearance of the final product. This is achieved by using a combination of heat, airflow, and other drying methods to remove moisture from the product. The temperature and airflow can be adjusted to meet the specific requirements of the product, which helps to ensure that it reaches the ideal water resistance.

The combination of high efficiency, large capacity, and versatility make these dryers a valuable asset for companies that produce a wide range of products.The flexibility of these dryers allows for adjustments in temperature, humidity, and airflow to accommodate different products and achieve the desired moisture level. This can help to improve the quality of the final product and increase the production rate.

Technical Parameters of Mesh Belt Drying Machine

| Model | Electric/Gas/Diesel | Heating Temperature | Output | Applied Products Fuffs,Corn Flakes &Breakfast Cereals,Pet Food,Nutritional powder,Modified Starch etc | |

| LTD-3D Three-layer Electric Oven | 30kw/h | ~180℃ | 150kg/h | ||

| LTD-3G Three-layer Gas/Diesel Oven | 4.8-10m³(Gas) 5.1-10kg/h(Diesel) | ~180℃ | 150kg/h | ||

| LTD-3D II Three-layer Gas/Diesel Oven(longer) | 45kw/h | ~180℃ | 250kg/h | ||

| LTD-3D Three-layer Gas/Diesel Oven(longer) | 16-22m³/h(Gas) 7-14/h(diesel) | ~180℃ | 250kg/h | ||

| LTD-5D Five-layer Electric Oven | 60kw/h | ~180℃ | 250kg/h | ||

| LTD-5G Five-layer Gas/Diesel Oven | 16-22m³/h(Gas) 7-14kg/h(Diesel) | ~180℃ | 250kg/h | ||

| LTD-7D Seven-layer Electric Oven | 120kw/h | ~180℃ | 400-500kg/h | ||

| LTD-7G Seven-layer Gas/Diesel Oven | 10-28m³/h(Gas) 16-26.1kg/h(Diesel) | ~180℃ | 150kg/h | ||

| LTD-5PD Five-layer Dryer | 30kw/h | ~90℃ | 80-150kg/h | Extruder pellets,Artificial Rice | |

| LTD-7PD Seven-layer dryer | 48kw/h | ~90℃ | 180-250kg/h | ||

Advantages-Continous Belt Dryer

1. The dryer is suitable for drying of granular materials larger than 3mm, energy saving and high efficiency, fast drying speed, reliable and convenient.

2. It’s adopting the cross-circulation design of hot air, It has a side air chamber forcibly blows the hot air from the top and bottom directions and penetrates the material quickly, which has strong performance for material penetration, and the drying efficiency is improved more than others;

3.The circulation design returned most of the humid air to be recirculated to high-temperature dry hot air after removing moisture from the air, recycling hot air, and reducing heat waste; The thermal efficiency has been increased.

4. The machine is equipped with a moisture-exhausting system, and the moisture-discharging fan is stronger to exhaust the moisture, which improves the water-discharging efficiency and the moisture-discharging content can be adjustable;

5. The equipment consists of the transmission system, conveying system, hot air circulation system, moisture exhausting system, distribution system, waste disposal system, and control system.

6. The standard model is stainless steel chain plate conveying, a bigger hole design is more conducive to the penetration of hot air, It also has a conveyor side leaking protection device;

Heating Sources can be: steam heating, gas heating, electric heating;

That can be customized according to material and process requirements, plant layout, etc.;

Hot Air Cross Circulation Dryer/Drying Machine

Cross Circulation Efficient Dryers are specialized equipment designed for the high-capacity and high-moisture drying of various food products, such as soya protein, pet food, aquatic feed, and more. Cross Circulation Efficient Dryers are typically used to remove moisture from the products and improve their water resistance and appearance quality. The dryers use a hot air circulation bi-directional cross-flow method, where hot air is circulated through the dryer in a cross-flow pattern to penetrate the materials from top to bottom. A moisture exhaust fan is also included in the dryer to remove moisture from the products as they are dried. The design of the Cross Circulation Efficient Dryers allows for efficient and effective drying of large quantities of material, making it suitable for commercial and industrial applications. Customization options are also available according to the customer's specific needs, such as capacity, moisture level, temperature control, or any other requirements.

What is this High Efficiency By-Cross Dryer Used for?

Cross Circulation Efficient Dryers are versatile machines that can be used to dry a wide range of products. As you mentioned, these dryers can be used to dry food products such as fruits, vegetables, meat, fish, seafood, grains, nuts, and many other types of food products. It can also be used in the feed industry to dry animal feed, pet food, and aquatic feed.

In addition, these dryers can also be used in other industries such as the pharmaceutical, chemical, and wood products industries, to dry powders, granules, tablets, and wood chips. It can also be used for drying materials such as grains, herbs, spices, and many other types of products. The efficiency and versatility of this type of dryer make it a valuable asset for many different types of manufacturing and production processes.

High-efficiency dryers are designed to effectively and efficiently remove moisture from a wide range of products.This also helps to maintain the shape, color, and texture of the product, ensuring a good quality finished product.the dryer may also include temperature and humidity sensors, which allow for real-time monitoring and control of the drying process. This can ensure that the drying process is done at the optimal conditions for the product, and prevent any damage to the product.

The large capacity dryers are also equipped with features that are designed to improve the water resistance and appearance of the final product. This is achieved by using a combination of heat, airflow, and other drying methods to remove moisture from the product. The temperature and airflow can be adjusted to meet the specific requirements of the product, which helps to ensure that it reaches the ideal water resistance.

The combination of high efficiency, large capacity, and versatility make these dryers a valuable asset for companies that produce a wide range of products.The flexibility of these dryers allows for adjustments in temperature, humidity, and airflow to accommodate different products and achieve the desired moisture level. This can help to improve the quality of the final product and increase the production rate.

Technical Parameters of Mesh Belt Drying Machine

| Model | Electric/Gas/Diesel | Heating Temperature | Output | Applied Products Fuffs,Corn Flakes &Breakfast Cereals,Pet Food,Nutritional powder,Modified Starch etc | |

| LTD-3D Three-layer Electric Oven | 30kw/h | ~180℃ | 150kg/h | ||

| LTD-3G Three-layer Gas/Diesel Oven | 4.8-10m³(Gas) 5.1-10kg/h(Diesel) | ~180℃ | 150kg/h | ||

| LTD-3D II Three-layer Gas/Diesel Oven(longer) | 45kw/h | ~180℃ | 250kg/h | ||

| LTD-3D Three-layer Gas/Diesel Oven(longer) | 16-22m³/h(Gas) 7-14/h(diesel) | ~180℃ | 250kg/h | ||

| LTD-5D Five-layer Electric Oven | 60kw/h | ~180℃ | 250kg/h | ||

| LTD-5G Five-layer Gas/Diesel Oven | 16-22m³/h(Gas) 7-14kg/h(Diesel) | ~180℃ | 250kg/h | ||

| LTD-7D Seven-layer Electric Oven | 120kw/h | ~180℃ | 400-500kg/h | ||

| LTD-7G Seven-layer Gas/Diesel Oven | 10-28m³/h(Gas) 16-26.1kg/h(Diesel) | ~180℃ | 150kg/h | ||

| LTD-5PD Five-layer Dryer | 30kw/h | ~90℃ | 80-150kg/h | Extruder pellets,Artificial Rice | |

| LTD-7PD Seven-layer dryer | 48kw/h | ~90℃ | 180-250kg/h | ||

Advantages-Continous Belt Dryer

1. The dryer is suitable for drying of granular materials larger than 3mm, energy saving and high efficiency, fast drying speed, reliable and convenient.

2. It’s adopting the cross-circulation design of hot air, It has a side air chamber forcibly blows the hot air from the top and bottom directions and penetrates the material quickly, which has strong performance for material penetration, and the drying efficiency is improved more than others;

3.The circulation design returned most of the humid air to be recirculated to high-temperature dry hot air after removing moisture from the air, recycling hot air, and reducing heat waste; The thermal efficiency has been increased.

4. The machine is equipped with a moisture-exhausting system, and the moisture-discharging fan is stronger to exhaust the moisture, which improves the water-discharging efficiency and the moisture-discharging content can be adjustable;

5. The equipment consists of the transmission system, conveying system, hot air circulation system, moisture exhausting system, distribution system, waste disposal system, and control system.

6. The standard model is stainless steel chain plate conveying, a bigger hole design is more conducive to the penetration of hot air, It also has a conveyor side leaking protection device;

Heating Sources can be: steam heating, gas heating, electric heating;

That can be customized according to material and process requirements, plant layout, etc.;