| Availability: | |

|---|---|

| Quantity: | |

Product Description

The solid block material measuring and packaging machine is an automated equipment specially used for measuring and packaging solid block materials.It has the following main features and functions:

High-precision measurement:The solid block material measuring and packaging machine is equipped with a precise measurement system,which usually uses a load cell or volume measuring device to achieve high-precision measurement.Ensure product packaging accuracy and consistency by accurately measuring the weight or volume of each package.

Multiple metering methods:This model usually provides multiple metering methods to adapt to different types and sizes of solid block materials.For example, a counter can be used for measurement,or a volume measuring device can be used for volume measurement.Depending on the characteristics of the specific material and packaging requirements,the most suitable metering method can be selected.

Automated operation:The solid block material metering and packaging machine adopts an automated control system,which can realize automatic feeding,metering, packaging and sealing operations.It is usually equipped with conveying equipment to convey materials to a measuring device,and then automatically puts the measured materials into packaging bags and performs sealing operations.No manual intervention is required, improving production efficiency and packaging consistency.

Flexible packaging forms: The equipment can adapt to different packaging forms, such as three-dimensional bags, cartons, cans, etc. According to the characteristics of the product and market demand, flexible packaging form selection and switching can be carried out to provide diversified packaging solutions.

Automatic adjustment and stable operation: Solid block material metering and packaging machines are usually equipped with advanced control systems, such as PLC (programmable logic controller), with automatic adjustment functions. According to the set parameters and requirements, the material measurement and packaging speed can be automatically adjusted to ensure the stability and consistency of the packaging process.

Visual operation interface: This model usually has a user-friendly operation interface, such as a touch screen, which provides an intuitive operation interface and parameter settings to facilitate the operator's setting and monitoring. The operation is simple and convenient, reducing the difficulty of manual operation.

The solid block material measuring and packaging machine can achieve high-precision measurement and automatic packaging of solid block materials, improve production efficiency, and ensure packaging quality and consistency. It is widely used in packaging of bulk materials in food, medicine, chemical and other industries.

Application Display

The solid block material metering and packaging machine is suitable for packaging a variety of solid block materials, mainly including the following categories of products:

Food products: such as candies, puffed foods, nuts, dried fruits, chocolate, biscuits, oatmeal and other solid block food products.

Chemical products: such as fertilizer granules, plastic granules, chemical fertilizer granules, pigment granules, rubber granules, etc.

Pharmaceutical products: such as capsules, solid tablets, granules, health products, etc.

Building materials products: such as sand and gravel particles, cement block materials, building material particles, etc.

Household products: such as washing powder, laundry detergent, dish soap and other solid block cleaning products.

Animal feed: such as pellet feed, solid block feed, feed additives, etc.

It should be noted that the solid block material metering and packaging machine may need to be adjusted and customized for different products according to their characteristics and requirements. According to the shape, size, weight and packaging requirements of the product, the appropriate equipment configuration and suitable measurement method can be selected to ensure the accuracy and consistency of packaging. Therefore, when purchasing a solid block material metering and packaging machine, you need to make a reasonable choice based on the actual product characteristics and packaging needs.

Product Advantages

High-precision measurement: The solid block material measurement and packaging machine is equipped with precision measurement devices, such as load cells, volume measurement devices, etc., which can achieve high-precision measurement. The weight or volume of each packaging bag can be accurately measured to ensure the accuracy and consistency of the packaging volume of the product.

Automated operation: The equipment adopts an automated control system and can realize automatic feeding, metering, packaging and sealing operations. It is usually equipped with conveying equipment to automatically convey materials to a metering device, and then automatically put them into packaging bags and perform sealing operations. No manual intervention is required, improving production efficiency and packaging consistency.

Multiple metering methods: Solid lump material metering and packaging machines usually provide multiple metering methods to adapt to different types and sizes of solid lump materials. The most suitable measurement method can be selected according to the characteristics of specific materials and packaging requirements, such as counter measurement, volume measurement, etc.

Flexible packaging forms: This model can adapt to different packaging forms, such as three-dimensional bags, cartons, cans, etc. According to product characteristics and market demand, flexible packaging form selection and switching can be performed to provide diversified packaging solutions.

Automatic adjustment and stable operation: Solid block material metering and packaging machines are usually equipped with advanced control systems, such as PLC (programmable logic controller), with automatic adjustment functions. According to the set parameters and requirements, the material measurement and packaging speed can be automatically adjusted to ensure the stability and consistency of the packaging process.

Reduce manual operations: The use of solid block material metering and packaging machines can reduce manual operations, reducing labor costs and work intensity. At the same time, it also reduces operator contact and improves the hygiene and safety of packaging.

Improve packaging efficiency and consistency: The solid block material metering and packaging machine has the characteristics of high-speed and continuous operation, which improves packaging efficiency. At the same time, automated operation and precise measurement can ensure the consistency of packaging and ensure consistent product quality and packaging effect for each package.

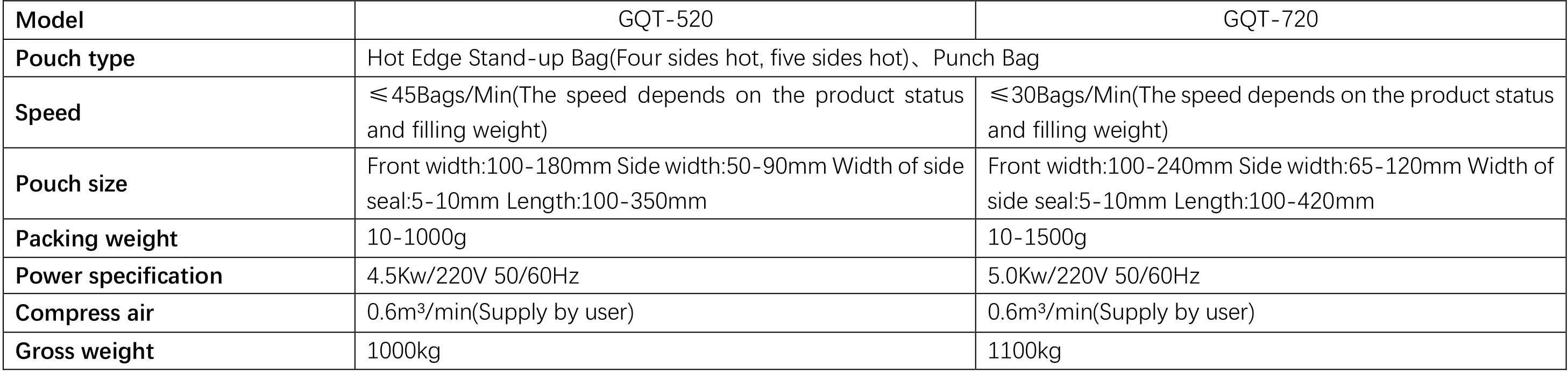

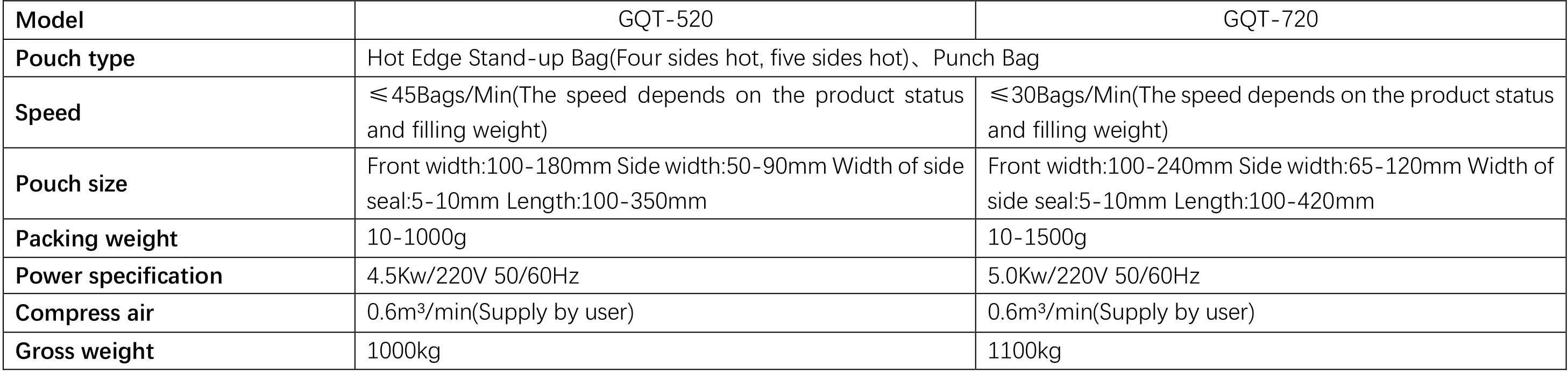

Specifications

Product Description

The solid block material measuring and packaging machine is an automated equipment specially used for measuring and packaging solid block materials.It has the following main features and functions:

High-precision measurement:The solid block material measuring and packaging machine is equipped with a precise measurement system,which usually uses a load cell or volume measuring device to achieve high-precision measurement.Ensure product packaging accuracy and consistency by accurately measuring the weight or volume of each package.

Multiple metering methods:This model usually provides multiple metering methods to adapt to different types and sizes of solid block materials.For example, a counter can be used for measurement,or a volume measuring device can be used for volume measurement.Depending on the characteristics of the specific material and packaging requirements,the most suitable metering method can be selected.

Automated operation:The solid block material metering and packaging machine adopts an automated control system,which can realize automatic feeding,metering, packaging and sealing operations.It is usually equipped with conveying equipment to convey materials to a measuring device,and then automatically puts the measured materials into packaging bags and performs sealing operations.No manual intervention is required, improving production efficiency and packaging consistency.

Flexible packaging forms: The equipment can adapt to different packaging forms, such as three-dimensional bags, cartons, cans, etc. According to the characteristics of the product and market demand, flexible packaging form selection and switching can be carried out to provide diversified packaging solutions.

Automatic adjustment and stable operation: Solid block material metering and packaging machines are usually equipped with advanced control systems, such as PLC (programmable logic controller), with automatic adjustment functions. According to the set parameters and requirements, the material measurement and packaging speed can be automatically adjusted to ensure the stability and consistency of the packaging process.

Visual operation interface: This model usually has a user-friendly operation interface, such as a touch screen, which provides an intuitive operation interface and parameter settings to facilitate the operator's setting and monitoring. The operation is simple and convenient, reducing the difficulty of manual operation.

The solid block material measuring and packaging machine can achieve high-precision measurement and automatic packaging of solid block materials, improve production efficiency, and ensure packaging quality and consistency. It is widely used in packaging of bulk materials in food, medicine, chemical and other industries.

Application Display

The solid block material metering and packaging machine is suitable for packaging a variety of solid block materials, mainly including the following categories of products:

Food products: such as candies, puffed foods, nuts, dried fruits, chocolate, biscuits, oatmeal and other solid block food products.

Chemical products: such as fertilizer granules, plastic granules, chemical fertilizer granules, pigment granules, rubber granules, etc.

Pharmaceutical products: such as capsules, solid tablets, granules, health products, etc.

Building materials products: such as sand and gravel particles, cement block materials, building material particles, etc.

Household products: such as washing powder, laundry detergent, dish soap and other solid block cleaning products.

Animal feed: such as pellet feed, solid block feed, feed additives, etc.

It should be noted that the solid block material metering and packaging machine may need to be adjusted and customized for different products according to their characteristics and requirements. According to the shape, size, weight and packaging requirements of the product, the appropriate equipment configuration and suitable measurement method can be selected to ensure the accuracy and consistency of packaging. Therefore, when purchasing a solid block material metering and packaging machine, you need to make a reasonable choice based on the actual product characteristics and packaging needs.

Product Advantages

High-precision measurement: The solid block material measurement and packaging machine is equipped with precision measurement devices, such as load cells, volume measurement devices, etc., which can achieve high-precision measurement. The weight or volume of each packaging bag can be accurately measured to ensure the accuracy and consistency of the packaging volume of the product.

Automated operation: The equipment adopts an automated control system and can realize automatic feeding, metering, packaging and sealing operations. It is usually equipped with conveying equipment to automatically convey materials to a metering device, and then automatically put them into packaging bags and perform sealing operations. No manual intervention is required, improving production efficiency and packaging consistency.

Multiple metering methods: Solid lump material metering and packaging machines usually provide multiple metering methods to adapt to different types and sizes of solid lump materials. The most suitable measurement method can be selected according to the characteristics of specific materials and packaging requirements, such as counter measurement, volume measurement, etc.

Flexible packaging forms: This model can adapt to different packaging forms, such as three-dimensional bags, cartons, cans, etc. According to product characteristics and market demand, flexible packaging form selection and switching can be performed to provide diversified packaging solutions.

Automatic adjustment and stable operation: Solid block material metering and packaging machines are usually equipped with advanced control systems, such as PLC (programmable logic controller), with automatic adjustment functions. According to the set parameters and requirements, the material measurement and packaging speed can be automatically adjusted to ensure the stability and consistency of the packaging process.

Reduce manual operations: The use of solid block material metering and packaging machines can reduce manual operations, reducing labor costs and work intensity. At the same time, it also reduces operator contact and improves the hygiene and safety of packaging.

Improve packaging efficiency and consistency: The solid block material metering and packaging machine has the characteristics of high-speed and continuous operation, which improves packaging efficiency. At the same time, automated operation and precise measurement can ensure the consistency of packaging and ensure consistent product quality and packaging effect for each package.

Specifications