| Availability: | |

|---|---|

| Quantity: | |

Product Description

The continuous belt dryer is compact and easy for operation.Double-pitch roller chain driving and circulating drying ensures steady and stable operation.Drying temperature and time is precisely controlled which results in perfect drying effect.The continuous belt dryer is designed with efficient energy saving system and heat distribution system, which ensures materials can be heated evenly at low energy consumption and high output operation conditions.The belt drying equipment provides uniform air velocity and temperature distribution. So, there is no need for diffuser plates.The internal baffles in the dryer enables us to control the airflow direction simply.Control system is available to enhance the dryer's performance and efficiency.

Application Display

Multi-Pass Dryer is continuous-production drying equipment. The dryer being widely used for drying the piece, strip and particle shape materials in good ventilation. The dryer is suitable for de-watering fruit & vegetable which the moisture content is high and high drying temperature is not allowed. Drying speed of belt dryer is fast, evaporation strength is high and the product quality is good.

Multi-Pass Dryer is widely used and support for drying various kind of material such as pigment, fiber, fruit & vegetable, briquette etc.

Product Advantages

food grade stainless steel mesh conveyor belt,free of damage to human body.

Drying temperature and time can be adjusted through the button on controller,capital drying effect;

World famous brand of electric parts,such as LG,FUJI,and Omron etc.

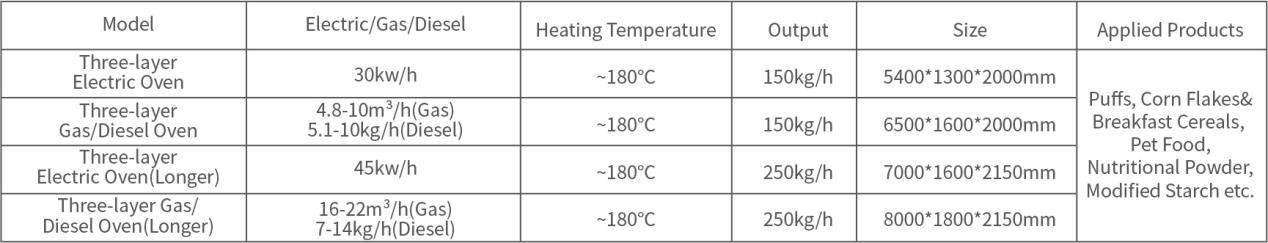

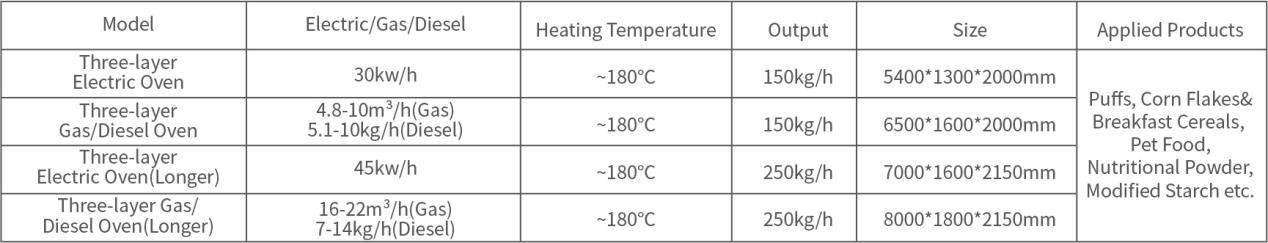

Various heating types are available, such as electric,gas,LPG,diesel and team.For non-electric type,Italian Baltur brand buner.

Insulated with aluminum silicate and exterior cover is 304 stainless steel.

For small granule,mesh cloth need to put on conveyor belt to avoid leakage from the mesh.

Different types of dryer can be made according to users' requirement based on layer,lenth,heating type,machine material etc

Product Description

The continuous belt dryer is compact and easy for operation.Double-pitch roller chain driving and circulating drying ensures steady and stable operation.Drying temperature and time is precisely controlled which results in perfect drying effect.The continuous belt dryer is designed with efficient energy saving system and heat distribution system, which ensures materials can be heated evenly at low energy consumption and high output operation conditions.The belt drying equipment provides uniform air velocity and temperature distribution. So, there is no need for diffuser plates.The internal baffles in the dryer enables us to control the airflow direction simply.Control system is available to enhance the dryer's performance and efficiency.

Application Display

Multi-Pass Dryer is continuous-production drying equipment. The dryer being widely used for drying the piece, strip and particle shape materials in good ventilation. The dryer is suitable for de-watering fruit & vegetable which the moisture content is high and high drying temperature is not allowed. Drying speed of belt dryer is fast, evaporation strength is high and the product quality is good.

Multi-Pass Dryer is widely used and support for drying various kind of material such as pigment, fiber, fruit & vegetable, briquette etc.

Product Advantages

food grade stainless steel mesh conveyor belt,free of damage to human body.

Drying temperature and time can be adjusted through the button on controller,capital drying effect;

World famous brand of electric parts,such as LG,FUJI,and Omron etc.

Various heating types are available, such as electric,gas,LPG,diesel and team.For non-electric type,Italian Baltur brand buner.

Insulated with aluminum silicate and exterior cover is 304 stainless steel.

For small granule,mesh cloth need to put on conveyor belt to avoid leakage from the mesh.

Different types of dryer can be made according to users' requirement based on layer,lenth,heating type,machine material etc