| Availability: | |

|---|---|

| Quantity: | |

Product Description

Granule packaging machine is a device used to package granular materials (such as powder, granular food, medicine, etc.). Its main function is to quantitatively pack granular materials and put them into packaging bags for sealing to achieve product packaging and sealing.

Fully automatic granule packaging machine: The fully automatic granule packaging machine is a piece of equipment that can realize full automation and is used for packaging granular materials. Compared with traditional manual or semi-automatic packaging machines, fully automatic granule packaging machines have higher production efficiency and lower labor costs.

The fully automatic granule packaging machine consists of a packaging host, a ten-head computer combination scale, a support platform, a finished product conveyor and a Z-shaped material conveyor (including a vibration device). It adopts imported PLC full computer control system, human-machine interface, touch screen operation, simple and intuitive operation, and excellent performance. Using servo film transport system, the positioning is accurate and the packaging is beautiful. It has a complete automatic alarm protection function to minimize losses. The fully automatic granule packaging machine is widely used for puffed food, crispy rice, jelly, candy, pistachios, dumplings, glutinous rice balls, pet food, miscellaneous grains and other items. It can greatly improve packaging efficiency and accuracy, reduce manpower input, reduce labor costs, and at the same time also Ensures consistency and reliability of packaging quality.

Automatic granule packaging machine: The automatic granule packaging machine is efficient, accurate, and reliable, and can improve production efficiency and packaging quality, and reduce labor costs. Automatic granule packaging machines usually include the following main components:

Supply system: used to automatically supply granular materials into packaging containers (such as cups, bags, etc.) of the packaging machine. The supply system can use devices such as vibrating disks, screw conveyors, and vibrating conveyor belts to deliver granular materials to packaging containers through vibration or transmission.

Weighing device: used to accurately measure the weight or capacity of granular materials to ensure the accuracy and consistency of packaged products. Weighing devices usually use high-precision electronic scales or volume meters and other equipment.

Packaging container: A container used to receive and hold granular materials, which can be a cup container, bag or other suitable packaging form. Packaging containers can be customized according to the different requirements of the product and can be made of different materials, shapes and sizes.

Sealing system: used to seal packaging containers to maintain the sealing and freshness of granular materials. The sealing system can use heat sealing, cold sealing, ultrasonic sealing and other technologies to ensure that the sealing is firm and meets product requirements.

Control system: used to control the automated operation of the entire packaging process. Usually, a PLC (programmable logic controller) or other similar controller is used to set automation parameters and processes through programming to realize automatic supply, weighing, sealing and other functions.

The main advantages of automatic granule packaging machines include high packaging efficiency, accurate weighing, reliable sealing, easy operation, etc. It is widely used in automatic packaging of loose, non-sticky and granular materials in food, medicine and chemical products, such as puffed food, fried food, shrimp crackers, potato chips, peanuts, oatmeal, granules, desiccant, salt, laundry Powder and other products meet the packaging needs of different granular materials and provide higher production capacity and quality assurance.

Granular series electronic quantitative packaging scale: This series of electronic scales is a net heavy-duty electronic scale that adopts the latest technology. It is suitable for weighing, measuring and packaging of irregular materials such as melon seeds, peanuts, lotus seeds, and walnuts. The feeding system of this series of electronic scales adopts a double vibrating door type for discharging materials, and has various processing modes such as large and small feeding and instant stop of blanking. This series of electronic scales effectively ensures the accuracy and speed of packaging.

In short, granule packaging machines are widely used in food, pharmaceutical, chemical and other industries, and can effectively improve production efficiency and packaging quality, and reduce labor costs. At the same time, the granule packaging machine can also be customized according to different packaging requirements to adapt to the needs of different materials and packaging specifications.

Application Display

Granule packaging machine is suitable for packaging a variety of granular products. Here are some common product examples:

Food particles: such as coffee powder, tea, candies, dried fruits and nuts, puffed foods, seasonings, instant soups, rice, flour, etc.

Pharmaceutical granules: such as granular drugs, health products, vitamins, herbal granules, etc.

Chemical particles: such as fertilizers, pesticides, granular additives, granular chemicals, etc.

Daily chemical product particles: such as skin care product particles, washing powder, hand sanitizer particles, shampoo particles, etc.

Building material particles: such as cement particles, sand, granular fillers, etc.

It should be noted that different granules have different physical properties and packaging requirements. Therefore, when selecting a granule packaging machine, you should customize it according to the specific product or select a suitable packaging machine model. We provide you with configurations and solutions for different products to meet your needs.

Product Advantages

Improve production efficiency: The granule packaging machine adopts automated operation, which is more efficient than traditional manual or semi-automatic packaging methods. It can automatically complete material supply, weighing, sealing and other links, greatly improving packaging speed and production capacity, and reducing manual operations and waiting time.

Ensure packaging accuracy: The granule packaging machine is equipped with a precise weighing device, which can accurately measure the weight or capacity of granular materials to ensure the accuracy and consistency of packaged products. Through a sophisticated control system, the filling amount of packaging cups or bags can be precisely controlled to avoid waste and over-packaging.

Improve packaging quality: The granule packaging machine adopts professional sealing technology, which can achieve reliable sealing effect and ensure the sealing and freshness of granular materials. Sealing systems usually include heat sealing, cold sealing, ultrasonic sealing and other methods, which are selected according to product characteristics and packaging requirements to ensure packaging quality and product safety.

Reduce labor costs: The automated operation of the granule packaging machine reduces reliance on labor, reducing labor costs and labor input. With only a small number of operators required for monitoring and adjustment, large-scale pellet packaging production can be achieved, improving production efficiency while reducing packaging quality problems caused by human errors and labor fatigue.

Flexibility and customizability: Pellet packaging machines are generally highly flexible and customizable. According to different granular materials and packaging requirements, it can be configured and adjusted to adapt to the packaging needs of different products. Different supply methods, sealing technologies, and packaging containers can be selected to meet the special requirements of different products.

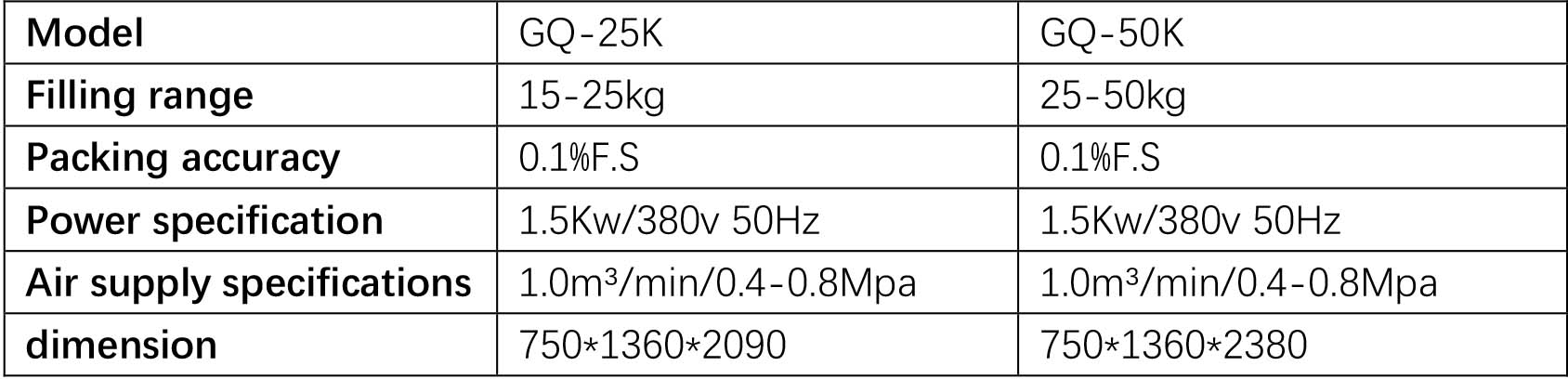

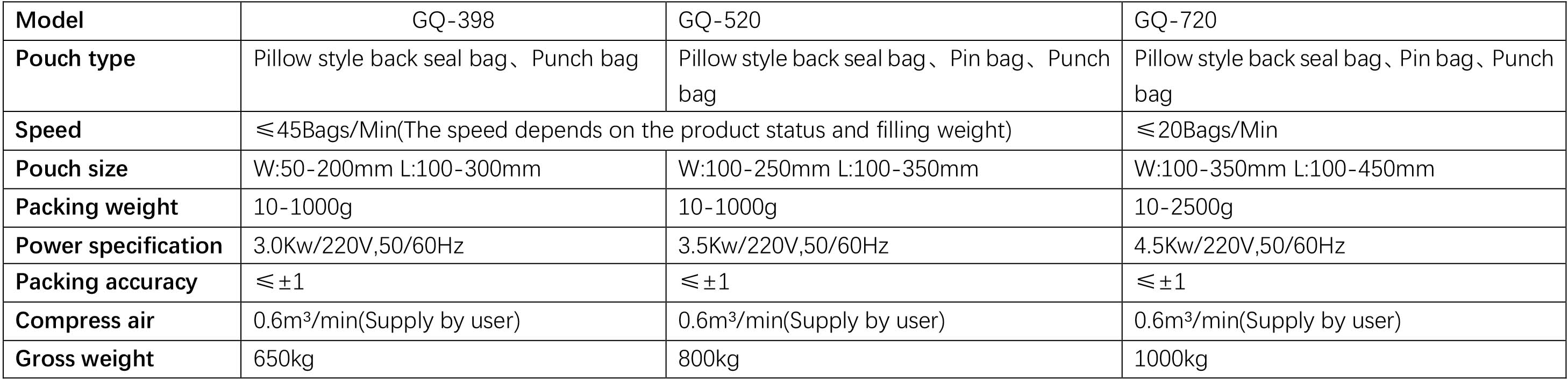

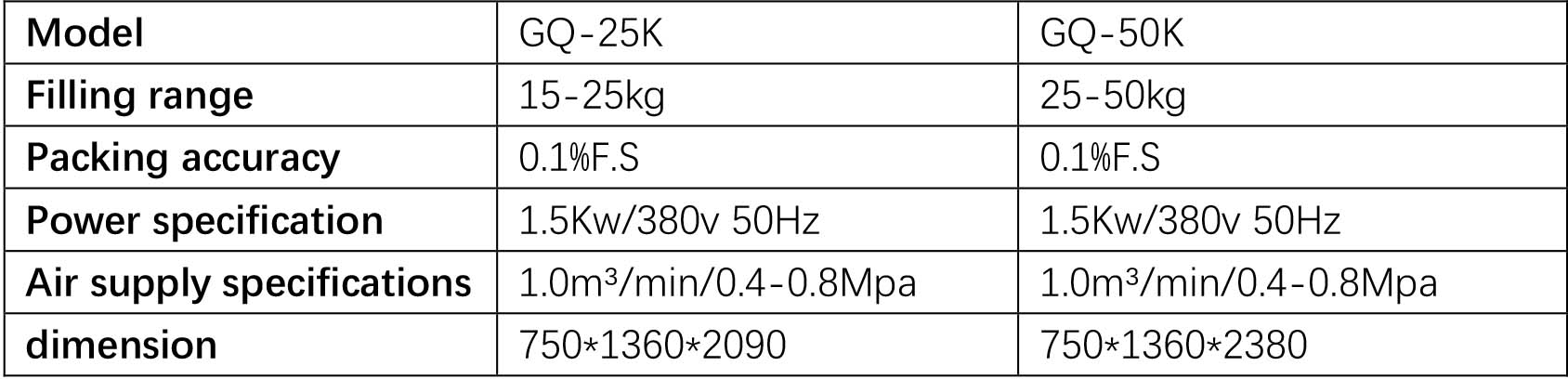

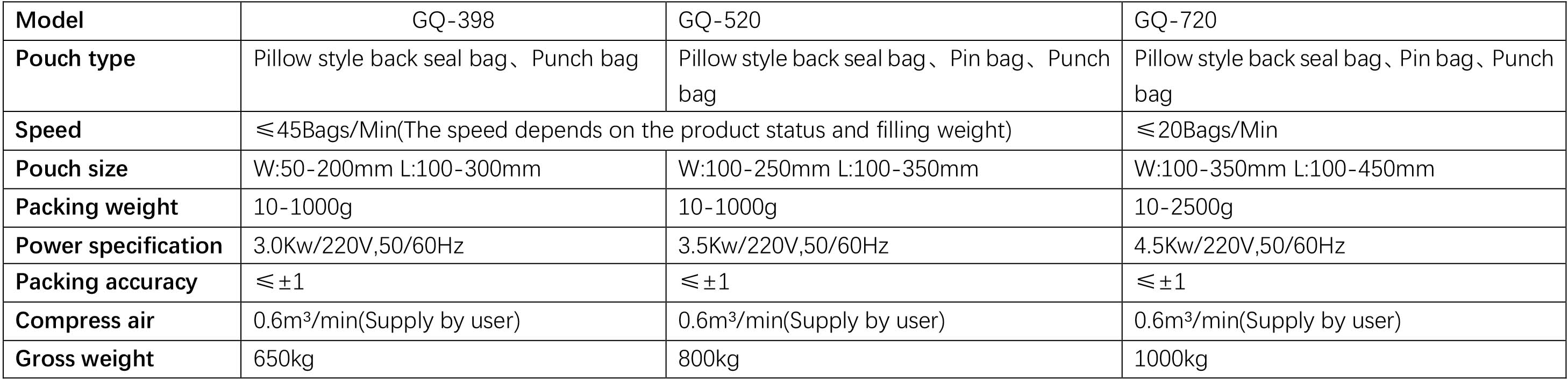

Specifications

Fully automatic granule packaging machine

Automatic granule packaging machine

Granular series electronic quantitative packaging scale

Product Description

Granule packaging machine is a device used to package granular materials (such as powder, granular food, medicine, etc.). Its main function is to quantitatively pack granular materials and put them into packaging bags for sealing to achieve product packaging and sealing.

Fully automatic granule packaging machine: The fully automatic granule packaging machine is a piece of equipment that can realize full automation and is used for packaging granular materials. Compared with traditional manual or semi-automatic packaging machines, fully automatic granule packaging machines have higher production efficiency and lower labor costs.

The fully automatic granule packaging machine consists of a packaging host, a ten-head computer combination scale, a support platform, a finished product conveyor and a Z-shaped material conveyor (including a vibration device). It adopts imported PLC full computer control system, human-machine interface, touch screen operation, simple and intuitive operation, and excellent performance. Using servo film transport system, the positioning is accurate and the packaging is beautiful. It has a complete automatic alarm protection function to minimize losses. The fully automatic granule packaging machine is widely used for puffed food, crispy rice, jelly, candy, pistachios, dumplings, glutinous rice balls, pet food, miscellaneous grains and other items. It can greatly improve packaging efficiency and accuracy, reduce manpower input, reduce labor costs, and at the same time also Ensures consistency and reliability of packaging quality.

Automatic granule packaging machine: The automatic granule packaging machine is efficient, accurate, and reliable, and can improve production efficiency and packaging quality, and reduce labor costs. Automatic granule packaging machines usually include the following main components:

Supply system: used to automatically supply granular materials into packaging containers (such as cups, bags, etc.) of the packaging machine. The supply system can use devices such as vibrating disks, screw conveyors, and vibrating conveyor belts to deliver granular materials to packaging containers through vibration or transmission.

Weighing device: used to accurately measure the weight or capacity of granular materials to ensure the accuracy and consistency of packaged products. Weighing devices usually use high-precision electronic scales or volume meters and other equipment.

Packaging container: A container used to receive and hold granular materials, which can be a cup container, bag or other suitable packaging form. Packaging containers can be customized according to the different requirements of the product and can be made of different materials, shapes and sizes.

Sealing system: used to seal packaging containers to maintain the sealing and freshness of granular materials. The sealing system can use heat sealing, cold sealing, ultrasonic sealing and other technologies to ensure that the sealing is firm and meets product requirements.

Control system: used to control the automated operation of the entire packaging process. Usually, a PLC (programmable logic controller) or other similar controller is used to set automation parameters and processes through programming to realize automatic supply, weighing, sealing and other functions.

The main advantages of automatic granule packaging machines include high packaging efficiency, accurate weighing, reliable sealing, easy operation, etc. It is widely used in automatic packaging of loose, non-sticky and granular materials in food, medicine and chemical products, such as puffed food, fried food, shrimp crackers, potato chips, peanuts, oatmeal, granules, desiccant, salt, laundry Powder and other products meet the packaging needs of different granular materials and provide higher production capacity and quality assurance.

Granular series electronic quantitative packaging scale: This series of electronic scales is a net heavy-duty electronic scale that adopts the latest technology. It is suitable for weighing, measuring and packaging of irregular materials such as melon seeds, peanuts, lotus seeds, and walnuts. The feeding system of this series of electronic scales adopts a double vibrating door type for discharging materials, and has various processing modes such as large and small feeding and instant stop of blanking. This series of electronic scales effectively ensures the accuracy and speed of packaging.

In short, granule packaging machines are widely used in food, pharmaceutical, chemical and other industries, and can effectively improve production efficiency and packaging quality, and reduce labor costs. At the same time, the granule packaging machine can also be customized according to different packaging requirements to adapt to the needs of different materials and packaging specifications.

Application Display

Granule packaging machine is suitable for packaging a variety of granular products. Here are some common product examples:

Food particles: such as coffee powder, tea, candies, dried fruits and nuts, puffed foods, seasonings, instant soups, rice, flour, etc.

Pharmaceutical granules: such as granular drugs, health products, vitamins, herbal granules, etc.

Chemical particles: such as fertilizers, pesticides, granular additives, granular chemicals, etc.

Daily chemical product particles: such as skin care product particles, washing powder, hand sanitizer particles, shampoo particles, etc.

Building material particles: such as cement particles, sand, granular fillers, etc.

It should be noted that different granules have different physical properties and packaging requirements. Therefore, when selecting a granule packaging machine, you should customize it according to the specific product or select a suitable packaging machine model. We provide you with configurations and solutions for different products to meet your needs.

Product Advantages

Improve production efficiency: The granule packaging machine adopts automated operation, which is more efficient than traditional manual or semi-automatic packaging methods. It can automatically complete material supply, weighing, sealing and other links, greatly improving packaging speed and production capacity, and reducing manual operations and waiting time.

Ensure packaging accuracy: The granule packaging machine is equipped with a precise weighing device, which can accurately measure the weight or capacity of granular materials to ensure the accuracy and consistency of packaged products. Through a sophisticated control system, the filling amount of packaging cups or bags can be precisely controlled to avoid waste and over-packaging.

Improve packaging quality: The granule packaging machine adopts professional sealing technology, which can achieve reliable sealing effect and ensure the sealing and freshness of granular materials. Sealing systems usually include heat sealing, cold sealing, ultrasonic sealing and other methods, which are selected according to product characteristics and packaging requirements to ensure packaging quality and product safety.

Reduce labor costs: The automated operation of the granule packaging machine reduces reliance on labor, reducing labor costs and labor input. With only a small number of operators required for monitoring and adjustment, large-scale pellet packaging production can be achieved, improving production efficiency while reducing packaging quality problems caused by human errors and labor fatigue.

Flexibility and customizability: Pellet packaging machines are generally highly flexible and customizable. According to different granular materials and packaging requirements, it can be configured and adjusted to adapt to the packaging needs of different products. Different supply methods, sealing technologies, and packaging containers can be selected to meet the special requirements of different products.

Specifications

Fully automatic granule packaging machine

Automatic granule packaging machine

Granular series electronic quantitative packaging scale