| Availability: | |

|---|---|

| Quantity: | |

Product Description

Powder packaging machine is a piece of equipment specially used for automatic packaging of powder products. It can efficiently and accurately fill powder into bags, bottles, boxes or other packaging containers, and complete operations such as sealing and marking. Powder packaging machines are widely used in food, medicine, chemicals, pesticides, cosmetics and other industries.

Fully automatic powder packaging machine: The fully automatic powder packaging machine has a simple structure, reliable operation and easy maintenance. This machine adopts rotating screw feeding, independent stirring system, servo coding and microcomputer control technology, which is the biggest technical feature of this machine. The fully automatic powder packaging machine integrates coding and control. It has the characteristics of sensitive movement, low noise, stability, reliability, fast measurement speed, high precision, and it also has a measurement number display.

The fully automatic powder packaging machine is suitable for the packaging needs of many powder products, such as food seasoning powder, milk powder, medicinal powder, cosmetic powder, etc. Through automation and high-precision operation, it can improve production efficiency, ensure packaging quality, reduce labor costs, and meet high standard requirements for powder product packaging.

Automatic powder packaging machine: The automatic powder packaging machine is a mechanical equipment specially used for automatic packaging of powder products. It can realize the automatic supply, weighing, packaging and sealing of powder products based on preset parameters and procedures, improving production efficiency and packaging accuracy. In general, the automatic powder packaging machine can realize automatic packaging of powder products and improve production efficiency, accuracy and consistency. It is suitable for the packaging needs of a variety of powder products, such as food powder, pharmaceutical powder, chemical powder, etc. Through automated operation and accurate weighing, packaging efficiency can be improved, packaging quality guaranteed, and labor costs reduced.

Powder series electronic quantitative packaging scale: adopts frequency conversion control and screw feeder to adapt to the flow speed of materials, with fast packaging speed and high packaging accuracy. It adopts a structure without measuring barrel, the whole machine is low in height and takes up little space. It can be used as a conveyor and sewing machine with tabletop lifting and lowering, and is multi-purpose. Specially designed with a bag tapping device and bag clamping and sealing mechanism, it is more suitable for packaging powder materials. Adaptable software, with functions such as automatic setting of control parameters, automatic correction of height differences, out-of-tolerance alarms, and self-diagnosis of faults.

In short, our powder packaging machine has the characteristics of simple structure, reliable circulator, easy maintenance, high precision, high efficiency, and no broken materials. Code synchronous control, sensitive movement, low noise, excellent performance, reliable measurement, fast speed and high precision. It can also display measurement counters. It adopts well-known brand PLC control system and wide touch screen, which is easy to operate. Customers can also choose checkweighers, metal detectors, and finished product conveyors as needed.

Application Display

Powder packaging machines are suitable for packaging a variety of powder products, including but not limited to products in the following fields:

Food industry: such as edible salt, sugar, flour, coffee powder, condiments, protein powder, milk powder, cocoa powder, instant beverage powder, bread crumbs, etc.

Chemical industry: such as chemical fertilizers, pesticides, pigments, dyes, washing powder, detergents, rubber powder, plastic powder, granular additives, etc.

Pharmaceutical industry: such as medicinal powder, herbal powder, health product powder, pharmaceutical intermediate powder, pharmaceutical coating materials, etc.

Daily chemical industry: such as perfume powder, spice powder, washing powder, facial cleanser powder, cosmetic powder, etc.

Hardware and mineral industry: such as sulfur powder, metal powder, ore powder, etc.

It should be noted that the properties and requirements of different powder products may be different. Therefore, when selecting a powder packaging machine, you need to consider the characteristics and packaging needs of the product to ensure the applicability and packaging effect of the machine. Some products may have special requirements for the material, sealing performance, moisture-proof performance, etc. of the powder packaging machine, so customers may need to fully communicate with us when selecting.

Product Advantages

Improve packaging efficiency: The powder packaging machine adopts automated operation and can quickly and accurately complete the powder packaging process, greatly improving packaging efficiency. Compared with manual packaging, powder packaging machines can save a lot of labor and time costs.

Accurate measurement and weighing: The powder packaging machine is equipped with a precision weighing device, which can achieve accurate measurement and weighing of powder products. The weight or capacity of each packaging unit can be precisely controlled, ensuring packaging accuracy and consistency.

Various packaging forms: The powder packaging machine has the ability to adapt to a variety of packaging forms, such as bags, bottles, cans, etc. According to different products and market demands, suitable packaging methods can be flexibly selected to meet the requirements of different forms of products.

Improve packaging quality: The powder packaging machine can achieve precise sealing and sealing operations to ensure the sealing and freshness of the product. It can effectively prevent powder products from getting damp, oxidized or contaminated, and improves packaging quality and product stability.

Flexibility and adjustability: Powder packaging machines usually have a certain degree of flexibility and adjustability and can be adjusted and configured according to different products and packaging requirements. The packaging needs of powder products of different sizes, weights or shapes can be adapted by changing molds or adjusting parameters.

Easy operation and maintenance: The powder packaging machine has a simple design and a friendly operation interface, and the operator can operate it easily with simple training. At the same time, it is generally more convenient for maintenance and upkeep, which can reduce maintenance costs and downtime.

Specifications

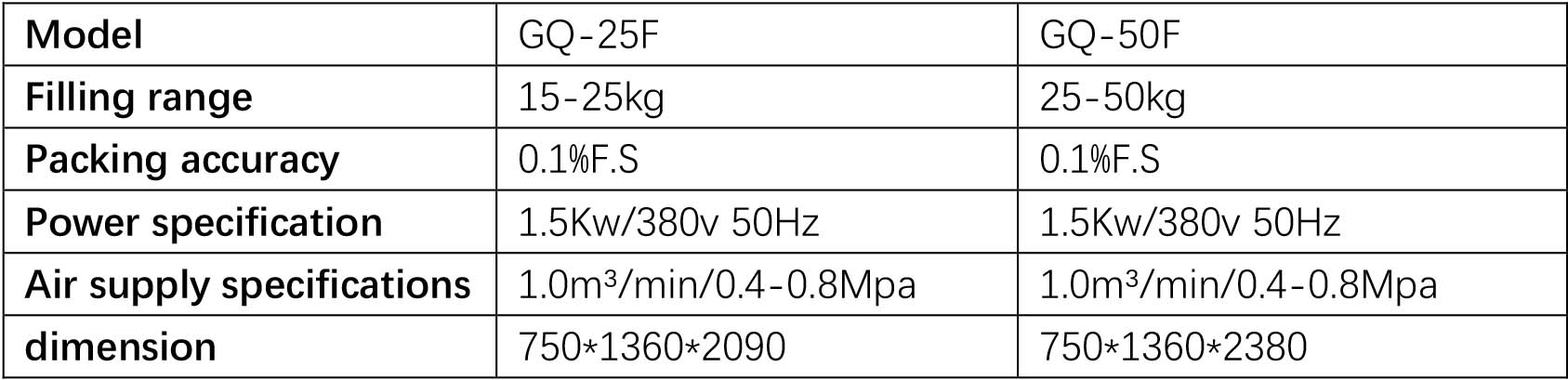

Fully automatic powder packaging machine

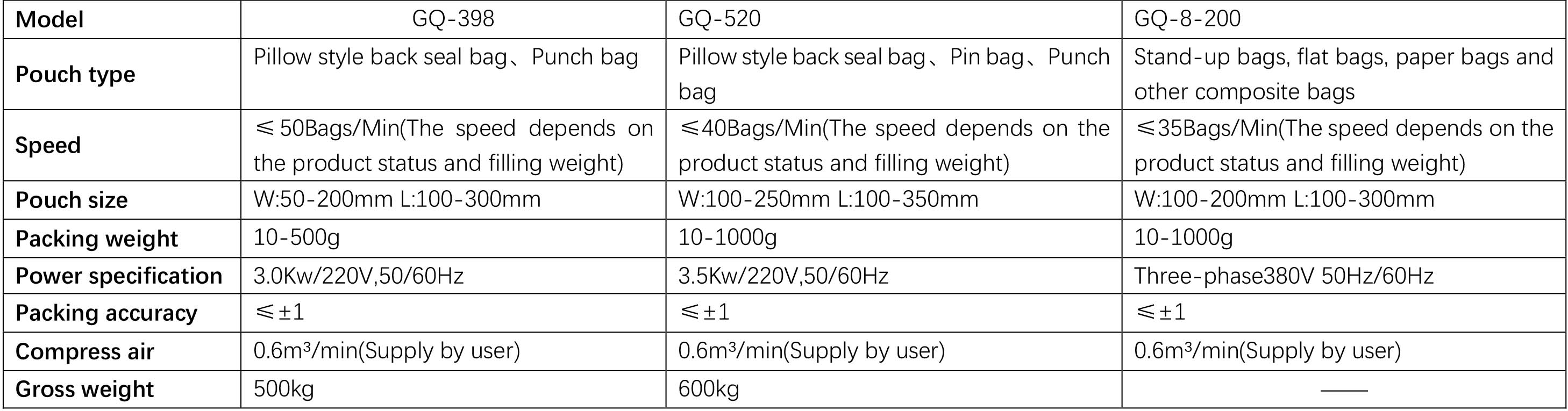

Automatic powder packaging machine

Powder series electronic quantitative packaging scale

Product Description

Powder packaging machine is a piece of equipment specially used for automatic packaging of powder products. It can efficiently and accurately fill powder into bags, bottles, boxes or other packaging containers, and complete operations such as sealing and marking. Powder packaging machines are widely used in food, medicine, chemicals, pesticides, cosmetics and other industries.

Fully automatic powder packaging machine: The fully automatic powder packaging machine has a simple structure, reliable operation and easy maintenance. This machine adopts rotating screw feeding, independent stirring system, servo coding and microcomputer control technology, which is the biggest technical feature of this machine. The fully automatic powder packaging machine integrates coding and control. It has the characteristics of sensitive movement, low noise, stability, reliability, fast measurement speed, high precision, and it also has a measurement number display.

The fully automatic powder packaging machine is suitable for the packaging needs of many powder products, such as food seasoning powder, milk powder, medicinal powder, cosmetic powder, etc. Through automation and high-precision operation, it can improve production efficiency, ensure packaging quality, reduce labor costs, and meet high standard requirements for powder product packaging.

Automatic powder packaging machine: The automatic powder packaging machine is a mechanical equipment specially used for automatic packaging of powder products. It can realize the automatic supply, weighing, packaging and sealing of powder products based on preset parameters and procedures, improving production efficiency and packaging accuracy. In general, the automatic powder packaging machine can realize automatic packaging of powder products and improve production efficiency, accuracy and consistency. It is suitable for the packaging needs of a variety of powder products, such as food powder, pharmaceutical powder, chemical powder, etc. Through automated operation and accurate weighing, packaging efficiency can be improved, packaging quality guaranteed, and labor costs reduced.

Powder series electronic quantitative packaging scale: adopts frequency conversion control and screw feeder to adapt to the flow speed of materials, with fast packaging speed and high packaging accuracy. It adopts a structure without measuring barrel, the whole machine is low in height and takes up little space. It can be used as a conveyor and sewing machine with tabletop lifting and lowering, and is multi-purpose. Specially designed with a bag tapping device and bag clamping and sealing mechanism, it is more suitable for packaging powder materials. Adaptable software, with functions such as automatic setting of control parameters, automatic correction of height differences, out-of-tolerance alarms, and self-diagnosis of faults.

In short, our powder packaging machine has the characteristics of simple structure, reliable circulator, easy maintenance, high precision, high efficiency, and no broken materials. Code synchronous control, sensitive movement, low noise, excellent performance, reliable measurement, fast speed and high precision. It can also display measurement counters. It adopts well-known brand PLC control system and wide touch screen, which is easy to operate. Customers can also choose checkweighers, metal detectors, and finished product conveyors as needed.

Application Display

Powder packaging machines are suitable for packaging a variety of powder products, including but not limited to products in the following fields:

Food industry: such as edible salt, sugar, flour, coffee powder, condiments, protein powder, milk powder, cocoa powder, instant beverage powder, bread crumbs, etc.

Chemical industry: such as chemical fertilizers, pesticides, pigments, dyes, washing powder, detergents, rubber powder, plastic powder, granular additives, etc.

Pharmaceutical industry: such as medicinal powder, herbal powder, health product powder, pharmaceutical intermediate powder, pharmaceutical coating materials, etc.

Daily chemical industry: such as perfume powder, spice powder, washing powder, facial cleanser powder, cosmetic powder, etc.

Hardware and mineral industry: such as sulfur powder, metal powder, ore powder, etc.

It should be noted that the properties and requirements of different powder products may be different. Therefore, when selecting a powder packaging machine, you need to consider the characteristics and packaging needs of the product to ensure the applicability and packaging effect of the machine. Some products may have special requirements for the material, sealing performance, moisture-proof performance, etc. of the powder packaging machine, so customers may need to fully communicate with us when selecting.

Product Advantages

Improve packaging efficiency: The powder packaging machine adopts automated operation and can quickly and accurately complete the powder packaging process, greatly improving packaging efficiency. Compared with manual packaging, powder packaging machines can save a lot of labor and time costs.

Accurate measurement and weighing: The powder packaging machine is equipped with a precision weighing device, which can achieve accurate measurement and weighing of powder products. The weight or capacity of each packaging unit can be precisely controlled, ensuring packaging accuracy and consistency.

Various packaging forms: The powder packaging machine has the ability to adapt to a variety of packaging forms, such as bags, bottles, cans, etc. According to different products and market demands, suitable packaging methods can be flexibly selected to meet the requirements of different forms of products.

Improve packaging quality: The powder packaging machine can achieve precise sealing and sealing operations to ensure the sealing and freshness of the product. It can effectively prevent powder products from getting damp, oxidized or contaminated, and improves packaging quality and product stability.

Flexibility and adjustability: Powder packaging machines usually have a certain degree of flexibility and adjustability and can be adjusted and configured according to different products and packaging requirements. The packaging needs of powder products of different sizes, weights or shapes can be adapted by changing molds or adjusting parameters.

Easy operation and maintenance: The powder packaging machine has a simple design and a friendly operation interface, and the operator can operate it easily with simple training. At the same time, it is generally more convenient for maintenance and upkeep, which can reduce maintenance costs and downtime.

Specifications

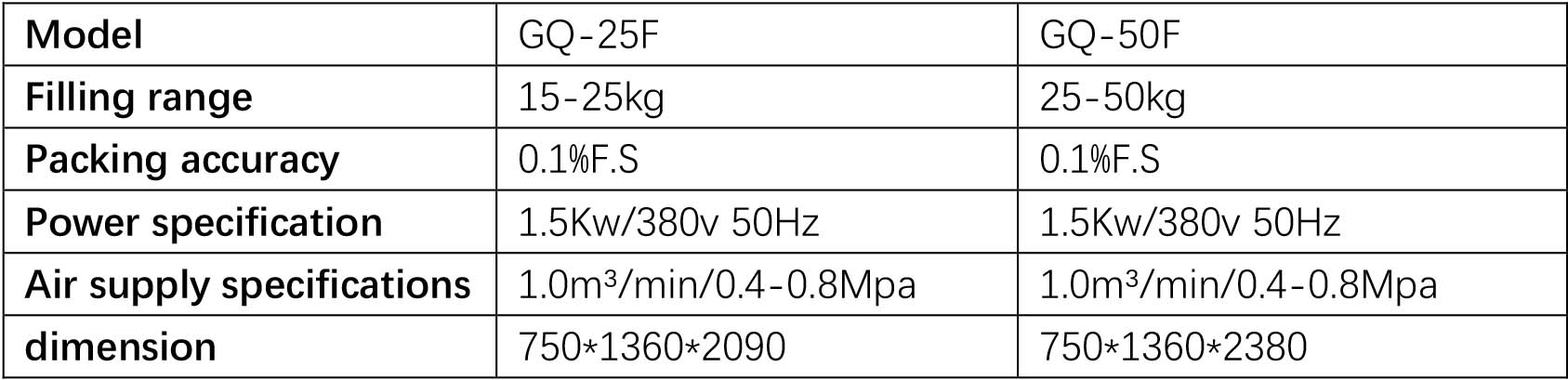

Fully automatic powder packaging machine

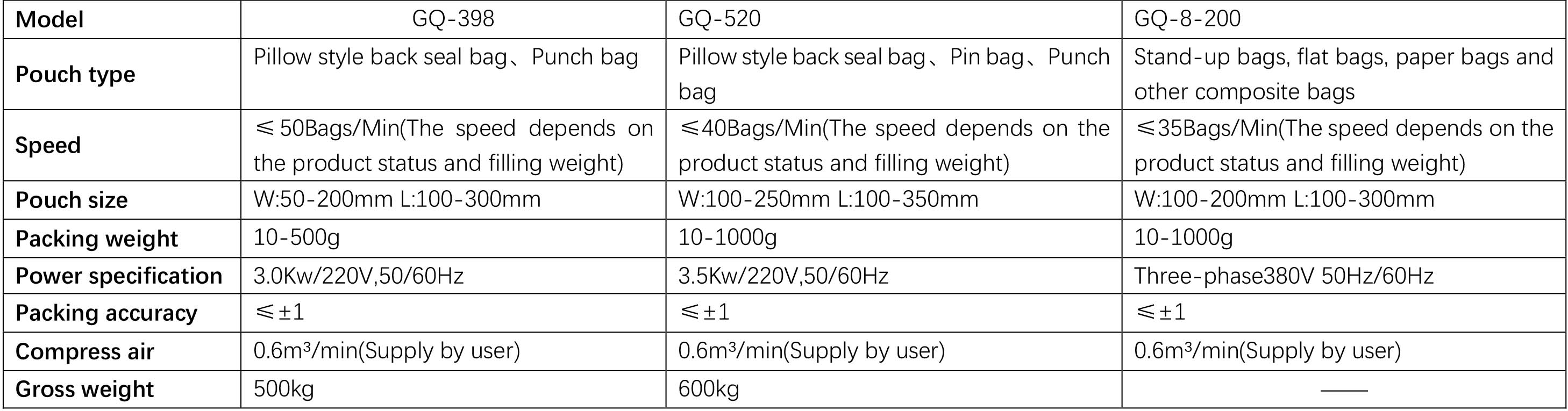

Automatic powder packaging machine

Powder series electronic quantitative packaging scale